Our customer service team fields a lot of questions when it comes to using MEKP (Methyl Ethyl Ketone Peroxide) as a catalyst specifically for gelcoat applications. Here are some of the most frequently asked questions we receive and answers to help you with this critical compound.

What is the role of MEKP in gelcoat applications?

MEKP acts as a catalyst to initiate the curing process of the polyester resin in gelcoat, allowing it to harden and form a durable, protective layer on surfaces like boats, cars, and fiberglass structures.

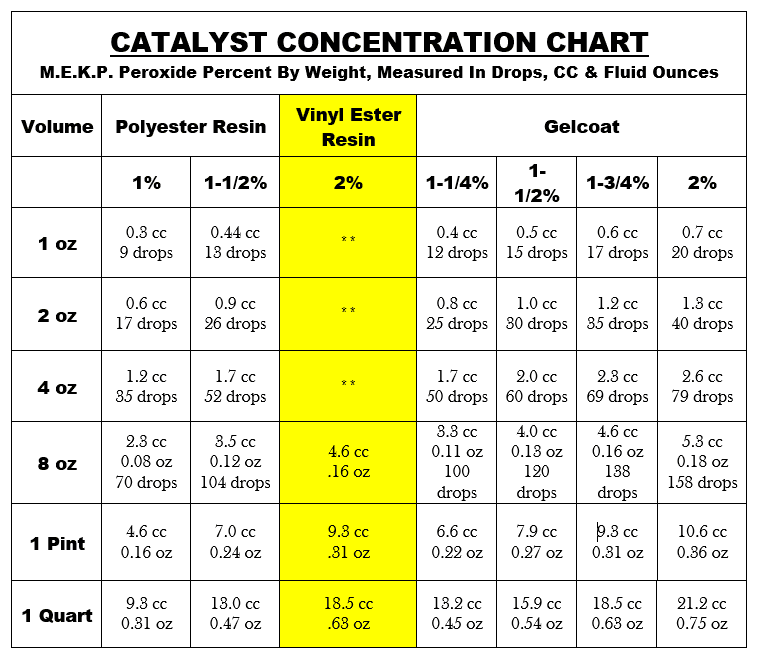

The typical ratio is 1-2% MEKP by weight of the gelcoat. However, the exact amount can vary depending on the gelcoat formulation, ambient temperature, and desired curing time.

How does temperature affect the curing process with MEKP in gelcoat?

Higher temperatures accelerate the curing process, while lower temperatures slow it down. It is crucial to adjust the MEKP amount based on the working environment to achieve the best results.

Can I adjust the gelcoat’s working time by changing the MEKP amount?

Yes, increasing the amount of MEKP will shorten the working time (pot life), while reducing it will extend the working time. However, altering the MEKP ratio too much can lead to incomplete curing or other issues.

What are the potential problems if too much or too little MEKP is used in gelcoat?

Using too much MEKP can cause the gelcoat to cure too quickly, leading to a brittle finish or excessive heat, which can cause warping. Too little MEKP can result in incomplete curing, leaving the surface tacky and vulnerable to damage.

What safety precautions should I take when using MEKP in gelcoat?

Always wear protective gloves, goggles, and a respirator. Work in a well-ventilated area and avoid any contact with skin or eyes. Store MEKP in a cool, dry place, and handle it carefully to prevent spills or exposure.

Can MEKP be mixed with pigments or additives in gelcoat?

Yes, but it is important to ensure that the pigments or additives are compatible with MEKP and do not interfere with the curing process. Always follow the manufacturer’s recommendations for mixing.

How do I know if the gelcoat has cured properly with MEKP?

Properly cured gelcoat will be hard, non-tacky, and have a consistent finish. If the surface is still tacky or soft after the recommended curing time, it may indicate insufficient MEKP or improper mixing.

What are the signs of improper curing in gelcoat when using MEKP?

Signs include a sticky or gummy surface, uneven hardening, poor adhesion, or excessive shrinkage. These issues can result from incorrect MEKP ratios, poor mixing, or adverse environmental conditions during curing.

How can I fix a gelcoat that hasn’t cured properly with MEKP?

If the gelcoat is only partially cured, additional MEKP can sometimes be applied, or the surface can be lightly sanded and recoated with a properly catalyzed mixture. In some cases, stripping the uncured gelcoat and reapplying it may be necessary.

These questions emphasize the importance of precise measurement, proper mixing, and environmental control when using MEKP as a catalyst in gelcoat applications to achieve the best results. MEKP is included free of charge with all Gelcoat purchased through Bottom Paint Store.