When most people hear the term “Liquid Urethane,” they think of a thick, black substance used for coating surfaces. While this is correct, Liquid Urethane comes in many varieties with different purposes. For example, some Liquid Urethanes are designed to be applied very thin while others are much thicker. Additionally, there are variations in terms of density – some liquids are denser than others – which affects how they should be used. In this blog post, we will look at what Liquid Urethane is, what its various uses are, and how density affects its application.

What is liquid urethane and what are its uses

Urethane is a liquid polymer that has a wide variety of uses. It is used in the production of plastics, coatings, adhesives, and sealants. Liquid urethane is also used as an insulation material and as a filler for composite materials. In addition, liquid urethane can be used to create dental implants and prosthetic devices.

How is liquid urethane density measured?

To measure the density of liquid urethane, you’ll need a graduated cylinder and a weight scale. First, weigh the graduated cylinder on the scale to get an empty weight. Then, fill the cylinder with liquid urethane and weigh it again. Subtracting the empty weight from the full weight will give you the total weight of liquid urethane in the cylinder. To calculate the density, simply divide this weight by the volume of liquid urethane in the cylinder. This will give you a density measurement in grams per cubic centimeters (g/cc).

The density of liquid urethane is measured in a variety of ways, depending on the intended use of the urethane. For example, the weight per gallon is often used to calculate the costs of shipping and handling. The pound per cubic foot is also used to calculate the volume of urethane needed for a given job. In both cases, the density of liquid urethane is calculated by dividing the weight of the urethane by its volume.

What factors affect the density of liquid urethane

The density of liquid urethane can be affected by a variety of factors, including its composition, temperature, and pressure. Urethane is a polymer that can be made from a variety of monomers, or small molecules. The type of monomer used will affect the urethane’s density. For example, using a heavier monomer will result in a denser urethane. Temperature can also affect the density of liquid urethane; as temperature increases, the urethane will expand and become less dense. Finally, liquid urethane is usually stored under pressure to keep it from expanding. If the pressure is too high, the liquid urethane can become dense and difficult to work with. By understanding these factors, it is possible to control the density of liquid urethane and choose the right product for your needs.

There are many factors that can affect the density of liquid urethane. The first is the temperature of the liquid urethane. The colder the liquid urethane, the denser it will be. The second factor is the pressure of the liquid urethane. The higher the pressure, the denser the liquid urethane will be. The third factor is the type of liquid urethane. Some types of liquid urethane are denser than others. The fourth factor is the amount of liquid urethane. The more liquid urethane there is, the denser it will be. Finally, the fifth factor is the presence of impurities in the liquid urethane. If there are impurities present, they can make the liquid urethane denser.

Examples of where to use liquid urethane with different densities

There are many different uses for liquid urethane. The material can be used as a sealant, adhesive, or even a casting material. When choosing a liquid urethane, it is important to consider the density of the material. A high-density urethane may be better suited for a heavy-duty application, while a low-density urethane may be more suitable for a lightweight application.

Here are some examples of where to use liquid urethane with different densities:

- Use a high-density urethane as an adhesive for bonding metal to concrete.

- Use a low-density urethane as a sealant for gaps and cracks around doors and windows.

- Use a medium-density urethane as a casting material for creating prototypes or models.

No matter what the application, liquid urethane can be a versatile and durable solution. By carefully selecting the right density for the job, it is possible to achieve excellent results.

How to select the right liquid urethane for your needs

How do you know which one is right for your project? Here are a few things to keep in mind:

The first thing you need to consider is what you’ll be using the liquid urethane for. There are different formulas for different applications, so you need to make sure you get the right one.

Next, think about the properties you need your liquid urethane to have. For example, do you need it to be clear or opaque? UV resistant? Heat resistant? Each type of liquid urethane has different properties, so it’s important to select the one that best meets your needs.

Once you’ve narrowed down your choices, it’s time to start testing. The best way to do this is to buy small quantities of each type of liquid urethane and try them out. This will help you see how they perform in real-world conditions and narrow down your options even further.

Finally, once you’ve selected the liquid urethane that’s right for you, make sure to follow the manufacturer’s instructions carefully. This will help ensure that you get the best results and avoid any problems down the road.

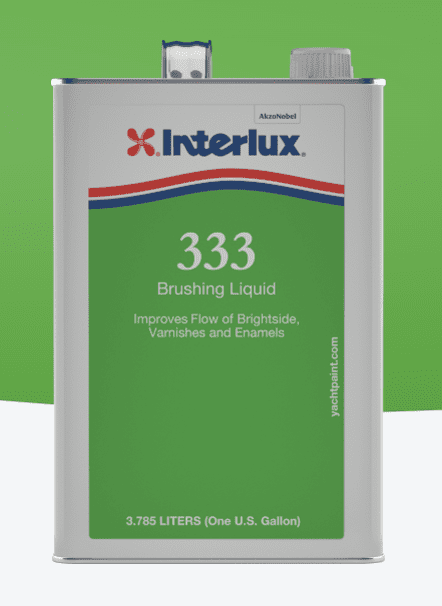

It is important to select the right liquid urethane for your needs to get the best results out of this versatile product. By understanding how density factors into its uses, you can be sure to select the correct liquid urethane for your specific project. Bottom Paint Store carries several different liquid urethane products including liquid urethane foam kits, which are a two-component, Isocyanate/Polyol based, pour-in-place, urethane foam system and Interlux Brushing Liquid 333, a slow drying solvent to ease brushing and facilitate the flow of specified paint coatings.

If you need additional information or ordering assistance on these liquid urethane products call our customer service team Monday through Friday 9:00 a.m.-5:00 p.m.